Spring Sponge

Spring Sponge X - A new era begins

In 2019, rubbers of the Dignics Family were first introduced, featuring improved Spring Sponge technology after an extensive research and development program at Butterfly TEC. Called "Spring Sponge X", the new technology allows for more precision and elasticity. This in turn lends rubbers of the Dignics Family higher values in Speed while making them easier to use in passive play due to increased elasticity. Spring Sponge X is a key component in the revolutionary characteristics of Butterfly's Dignics rubbers and is sure to find friends fast among table tennis players of all skill levels.

Following an extensive nine-year research program, Spring Sponge X was developed to generate more power. It response increased by 14%, with impact resilience enhanced by 3% compared to the current Spring Sponge; the result is a big difference in the level of power produced. Spring Sponge X is the key to bringing high performance to Dignics.

As a result of pursuing more power, the hardness degree of the adopted sponge is 40°. It is four degrees harder than the Spring Sponge applied to the Tenergy series. However, thanks to the improved flexibility level, a softer feeling is achieved despite the high value of 40°. In general, the harder the sponge, the heavier the weight of a rubber. Spring Sponge X has the same weight as Spring Sponge applied to Tenergy, even four degrees harder than it. Therefore, ease of use is secured as the racket does not become too heavy, even if attached to both sides of a blade. A player with less power can also use it without a problem.

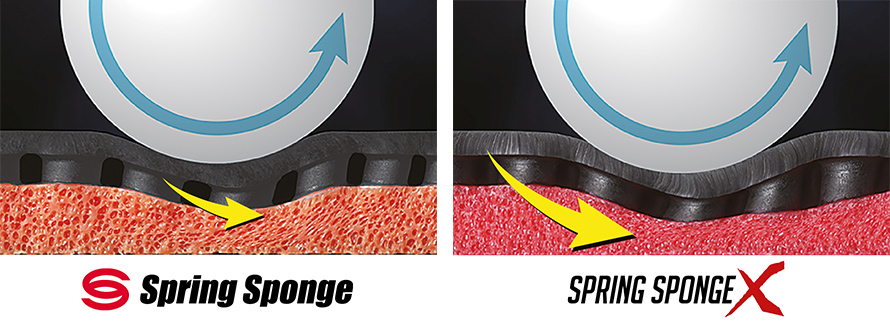

Ball impacts on rubber

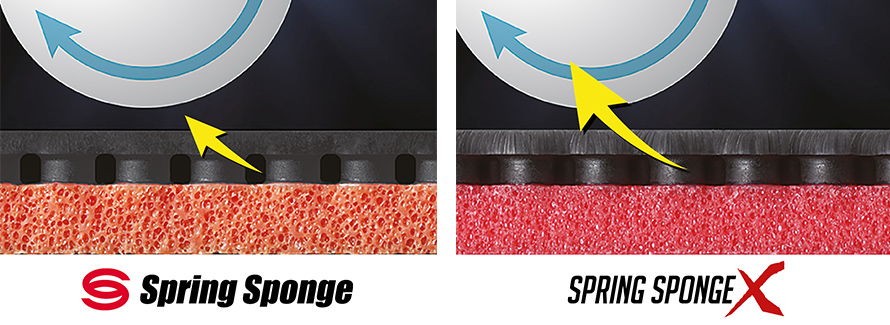

Ball bounces back

| Compression | Elasticity | |

| Traditional soft sponge | high | low |

| Traditional hard sponge | low | high |

|

high | high |

|

higher | higher |

SPRING SPONGE

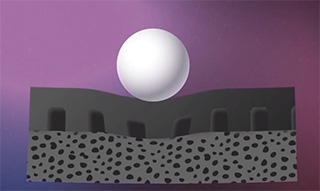

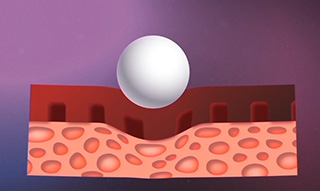

BUTTERFLY entered a new dimension by combining a new mixture of raw materials with a specific structure of the air bubbles inside the sponge. Spring Sponge supports the effect that the rubber holds on to the ball longer than usual. This created an extraordinary ball feeling which cannot be compared to the past rubbers.The premise was: How to increase the impact of the sponge without changing its thickness or texture? Finding the answer took time, but exceeded all expectations.

Spring Sponge supports the effect that the rubber holds on to the ball longer than usual. This created an extraordinary ball feeling which cannot be compared to the past rubbers.The premise was: How to increase the impact of the sponge without changing its thickness or texture? Finding the answer took time, but exceeded all expectations.

Rubbers with a traditional sponge absorb the energy of an incoming ball. Much like a matt with no feathers. The energy is lost and the ball only receives power only by the player's shot.

The Spring Sponge, however, is thinner and harder - but still elastic. The air compartments contract on impact and then expand again, imparting additional power on the ball. Much like a spring – hence the name, Spring Sponge.